If you export by sea, it’s (most likely) via a container. This can be both expensive and incredibly inefficient, if you use traditional packaging like wood or veneer in standard sizes. Often, you’re actually exporting mostly air.

Yes, you read that right.

AIR!

Before you click away in frustration, let us explain what we mean.

There are typically three types of containers loaded onto container ships:

20-foot, 40-foot, and 40-foot-high cube.

All three container types have a width of 2.35 meters.

Now, let’s assume you export using traditional packaging with standard dimensions (EU pallets 1200 mm x 800 mm).

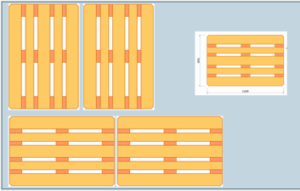

Shown here in the images, the blue-marked area represents the container, while the pallets are, well… the pallets.

You’ve probably already noticed—it doesn’t add up, and there will be wasted space. The same scenario occurs if we turn one pallet the other way, as shown below.

The wasted space in this case is 30 cm in width. Remember to multiply that 30 cm by the length of the container, because you lose 30 cm along the entire length of the container.

With our packaging, we customize the designs so they can be packed as shown in the white areas.

In the end, of course, it’s your product that determines the packaging dimensions, but the potential to optimize container packing is much greater with our packaging.

It’s all about thinking outside the box—and that’s something we have over 100 years of experience with.

Maybe you’re thinking, “Phew, good thing we don’t export by sea.”

Can you guess what the general picture is when it comes to space optimization for exports by road, rail, or air?

Scan the QR – to find your advisor